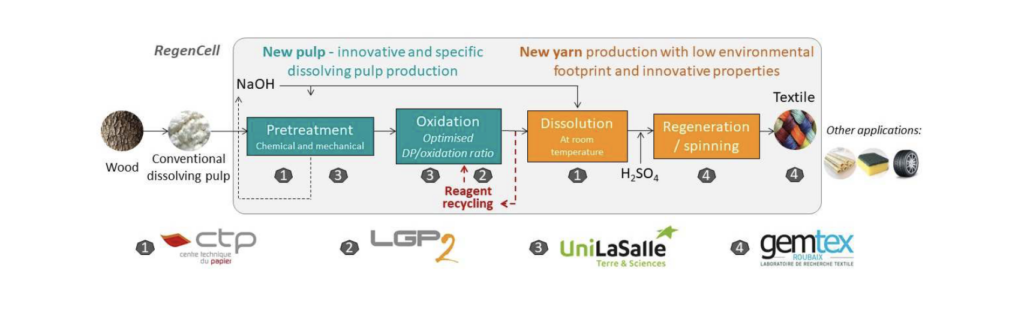

RegenCell aims to develop a new process for the production of textile yarns from dissolving wood pulp as an alternative to the polluting manufacture of viscose.

Based on promising preliminary results, three laboratories and a technical centre are proposing a sustainable and innovative solution for dissolving cellulose in a mild aqueous solution (soda) at room temperature. It combines

The process will be validated on a laboratory scale by a Life Cycle Assessment and two proofs of concept, namely a dissolving pulp whose dissolvability has been improved by controlled oxidation, and a new cellulosic technical textile with adaptable hydrophilicity and resistance characteristics.

Economic impacts are expected for:- the textile industry, with a reduction in its environmental footprint, leading to its possible relocation to Europe,- and the paper industry, with a diversification of the dissolving pulp markets, via the implementation of a new process that is energy-efficient and reactive, and easy to implement both in the pulp production plant and on the textile yarn production lines.

Contact for Ensait / Gemtex :

Start : 03/2023 – Stop : 02/2026

Partners : INP Grenoble, Centre Technqiue du papier, UNILASALLE, ENSAIT

Link on ANR website