Project objectives

The POCOMA project aims at developing passive polymer membrane for clothing in order to improve the thermal comfort felt by a person at rest through the control of Mid-InfraRed (Mid-IR) radiation.

Indeed, at rest, 50% of the heat loss of the human body is due to radiative loss in the Mid-IR range (5-11μm). We propose to control the temperature of the space located between the human skin and the textile, called microclimate (MC), by introducing a polymer membrane structured at the microscale to modulate the textile/Mid-IR interaction (transmission, reflexion and absorption in the 5-11μm range) and so the thermal behaviour at the macroscale.

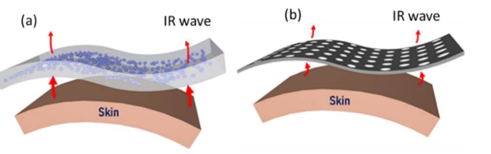

Two strategies will be developed, optimized and associated with each other (Figure 1): the fabrication of particle-charged membranes and photonic microstructured membranes. Quantitatively, our objective is thus to develop a solution to reduce the T° of a room by several degrees while ensuring a constant skin T° compatible with a feeling of comfort.

Figure 1 : Two membrane-based strategies to be optimized and associated within the POCOMA ANR project:

a) particle-charged and b) microstructured photonic crystal membranes.

The interest is here to understand and control the role of the optical radiations (absorption, reflection, scattering) in order to manage the thermal comfort. The project will be conducted under three main objectives: (1) the design of a set of polymer membranes textile compatible, changing their physical natureand geometrical structuration; (2) the fabrication of several demonstrators, their optical and thermal characterization at the laboratory scale, and (3) the complexation of the obtained membranes on usual textile and the path for large scale production.

Strategies description, scientific and technological barriers

The POCOMA project investigates two strategies for modulating the mid-infrared optical properties of polymer membranes by charging them with particles and/or structuring them at the microscopic scale. These two possibilities will be studied in modelling, in order to understand the link between optical and thermal properties, fabricated and characterized. They will be evaluated in terms of performance, and technical/economic feasibility on an industrial scale. We do believe that the association and combination of the proposed solutions will lead to original and promising results in relation to our objectives.

The first strategy is to insert particles into polymer membranes to modify the effective refractive index of the membrane [1] (Figure 1a). Introducing nanoparticles (NPs, size lower than the wavelength of interest) will lead to modify the reflection and absorption properties of the membrane in the Mid-IR range.

The second solution will be based on the geometric structuration of the membranes at the microscale, free of particles or not, in the aim to take benefit from photonic crystal properties, as photonic band gap or Fano- like resonances [2] (Figure 1b). The crucial point will be the fabrication of a periodic structuration at the microscale on samples of several meters, imposed by the textile application. Manufacturing techniques that allow us to move from standard microelectronics fabrication to production methods compatible with the industrial scale will thus be envisaged.

Period : Oct 2021 / Mar 2025

Keywords : membrane simulation – particles charged polymer membrane – microstructured polymer membranes – thermal characterization – laminating – coating –Micro/nanostructured membranes on textile

Website : ANR Pocoma

Partners : Inst.FOTON Institut Fonctions Optiques pour les Technologies de l’informatiON – JUNIA – DAMART DSB / DIO R&D – IEMN Institut d’Electronique, de Microélectronique et de Nanotechnologie

Ensait contact : Joseph LEJEUNE